Smart Strategies for Soft Signage

February 5th, 2026

Soft signage has quietly become one of the most requested solutions in the sign industry... and one of the easiest to underestimate.

On the surface, fabric graphics check all the boxes: lightweight, visually striking, and easy to ship and install. But behind the scenes, they introduce a different set of demands that don’t always show up in rigid production. Fabric requires more planning, tighter control, and clearer communication across sales, prepress, and finishing.

The shops seeing the best results aren’t chasing every fabric job that comes through the door. They’re building repeatable processes, setting smarter expectations, and treating soft signage as its own category, not a substitute for rigid prints.

With the right approach, fabric graphics can be both efficient and profitable. The following strategies focus on practical ways to reduce friction, improve consistency, and make soft signage work better for your operation.

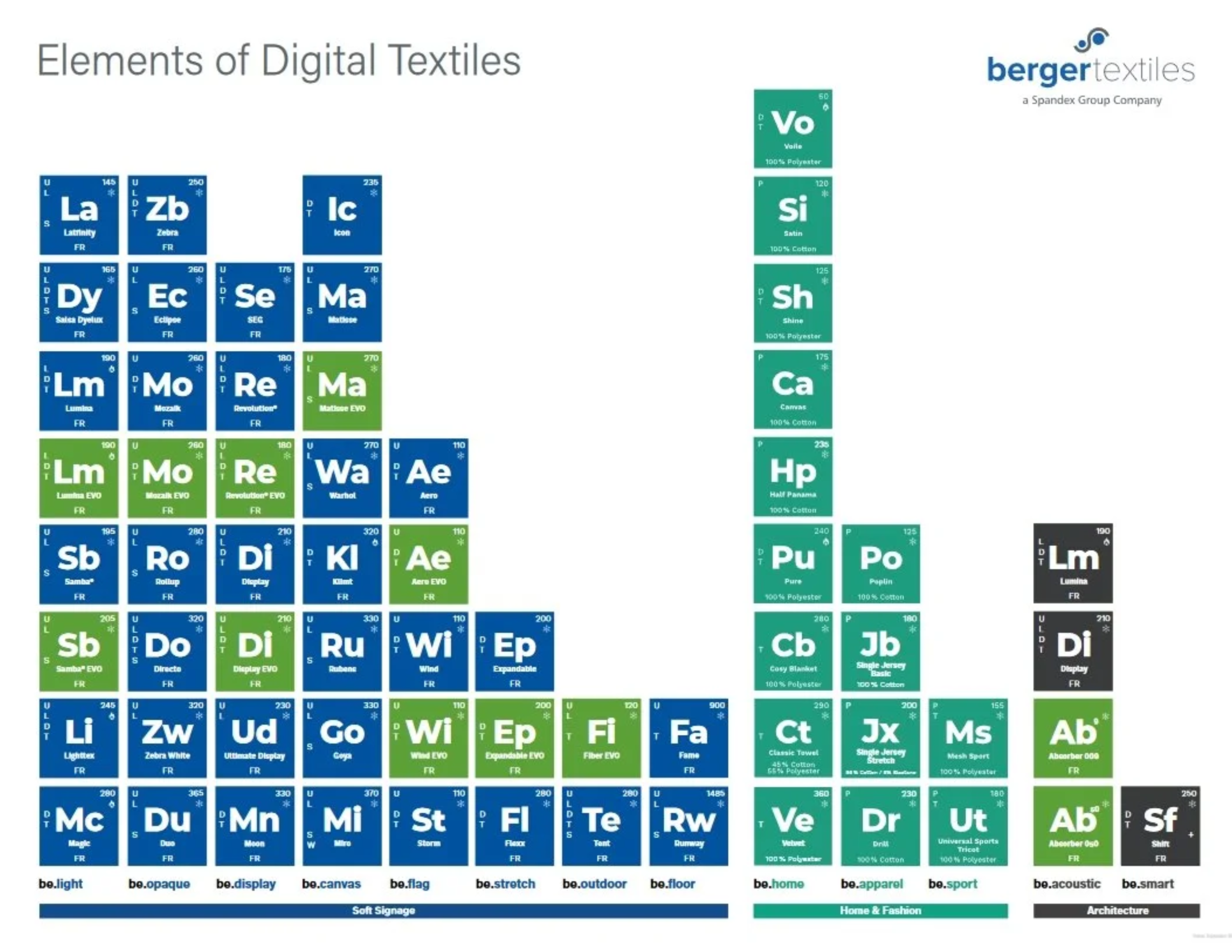

1. Choose the Right Product for the Application

Not every soft signage job has the same requirements, and using a one-size-fits-all fabric can create unnecessary challenges in production and finishing.

Start by matching the product to the application — whether it’s SEG frames, event backdrops, retail displays, flags, or wall coverings. Factors like fabric weight, stretch, opacity, flame retardancy, and intended use all affect print quality, handling, and final performance.

Selecting purpose-built materials upfront reduces reprints, simplifies finishing, and improves consistency across repeat orders. When the right product is chosen from the start, workflows run smoother and soft signage becomes easier to scale profitably.

Fabric Choice Matters

The fabric you choose has a direct impact on print consistency, finishing efficiency, and overall workflow.

Berger Textiles offers a wide range of digitally printable fabrics designed for soft signage applications like SEG, backdrops, displays, and flags. Their materials are built for reliable print performance and predictable finishing, making it easier for sign shops to standardize processes and reduce production variables.

2. Optimize Printer Scheduling and Workflow

Take a close look at how your wide-format printers are being used. Track uptime, changeovers, and job patterns over a few weeks.

Grouping jobs that use the same fabric types or color profiles can reduce calibration time and material waste. Realigning your schedule to minimize machine idle time and avoid unnecessary setups not only boosts efficiency, it also opens capacity for rush jobs that often command premium pricing.

3. Make Finishing Faster and More Consistent

Fabric signage often requires sewing, trimming, and frame finishing, steps that can slow production when they’re manual or inconsistent.

To reduce finishing time and variability, many shops are looking for alternatives that simplify attachment and assembly.

Adhesive-backed keder, like the option from Berger Textiles USA, eliminates the need for sewing while delivering clean, consistent edge finishes for SEG applications.

Combined with improved cutting tools, semi-automated finishing stations, and standardized procedures, solutions like adhesive-backed keder help reduce hands-on labor and speed up turnaround. Faster, more predictable finishing improves margins and makes your output more attractive to larger, repeat customers who rely on consistent quality.

4. Set Clear Expectations Before Jobs Hit Production

Many production issues with fabric graphics start long before printing begins.

Establish clear guidelines for artwork setup, color expectations, and sizing tolerances specific to fabric. Sharing these standards early — through artwork checklists or preflight notes — reduces revisions, prevents reprints, and keeps projects moving smoothly through production.

Clear expectations also build trust with customers who appreciate transparency and consistency.

5. Develop a Versatile, Well-Documented Team

Cross-training your staff pays dividends. Teach operators to work across multiple machines and finishing tasks so production isn’t dependent on a single individual.

At the same time, document key workflows, including color profiles, fabric handling best practices, and common troubleshooting steps, so your team can consistently reproduce quality results. A versatile, well-informed staff makes your operation more resilient during demand spikes and helps maintain fast turnarounds without adding headcount.

Here's the bottom line...

By simplifying your product mix, tightening production workflows, improving finishing efficiency, targeting the right buyers, and building a flexible team, you can turn growing soft signage demand into reliable, profitable growth. These strategic shifts help lower costs, increase capacity, and position your business as a dependable partner for high-impact visual solutions.

Looking for more ways to improve efficiency and profitability?

You can also shop our soft signage here: Our Products | Quality Media and Laminating Solutions